| |

|

|

| |

|

|

| |

|

|

| |

Pressing and Bending |

|

| |

|

|

| |

This department is home to machinery equipped for machining pipes and sheet metal: its main task. Various components are produced by cold plastic deformation using the powerful presses, and include: mixing chambers, brackets of various kinds, baffles, pressed Venturi. In addition, using CNC benders, pipes and sheet metal can be formed to produce manifolds, bends, bent Venturi etc.. Not all components are produced in this department since corporate policy calls for a part to be manufactured by independent specialized suppliers working per the company’s specifications. This avoids the high costs involved in managing a large number of production dies and templates. |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

Assembly |

|

| |

|

|

| |

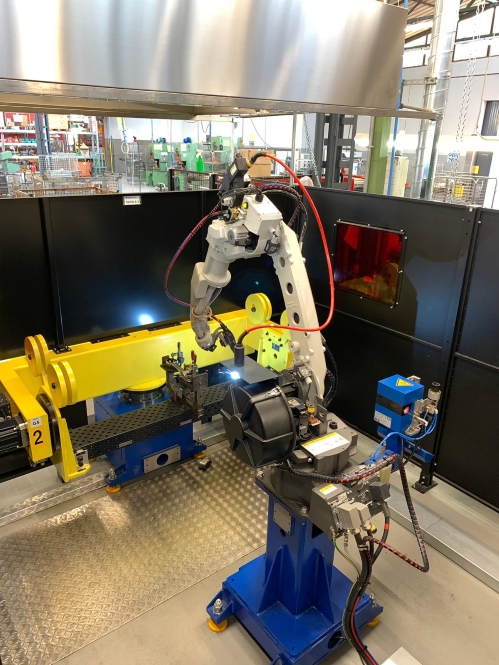

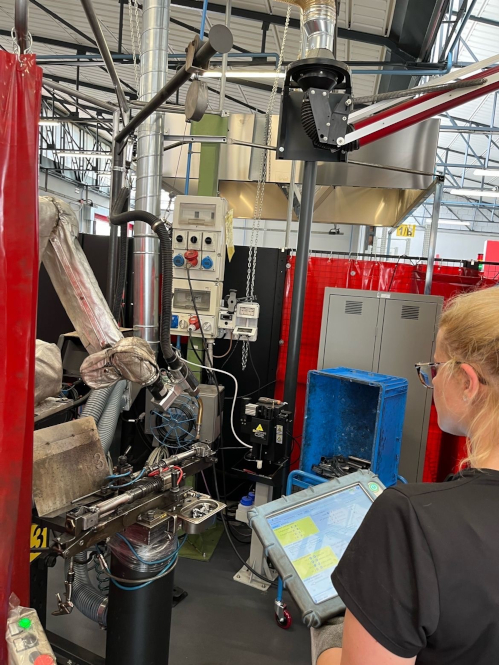

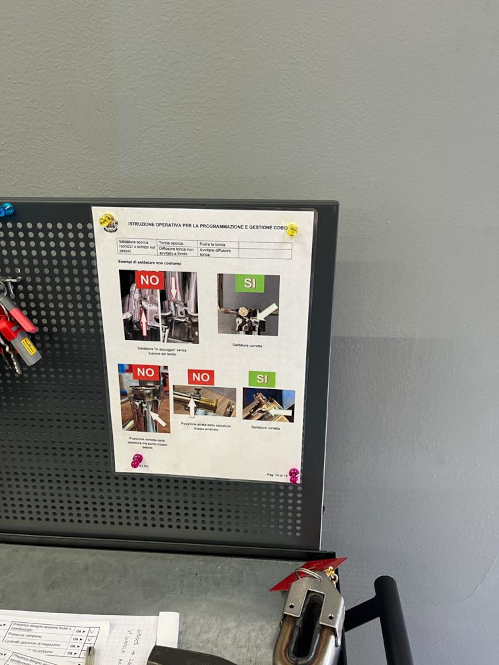

Components required to build a burner, coming from the departments described earlier, are put together in this department by arc welding: MIG, MAG, TIG, SPOT WELDING, INDUCTION. The type of welding depends on the component to be assembled and on what kind of material it is made from. For instance, manifolds are assembled with spot welding; brackets and fastening pins with MIG welding; half shells and gaskets with the TIG method. Most work is performed manually, though automatic devices are used for accurate, lengthy welding. The personnel working in this department are very aware of the importance of their contribution in terms of safety and reliability, and hence work with incomparable accuracy. The most important component, i.e. the pipe, is only welded in this department. Every production batch is made according to the production planning program, drawings, technical sheet and real burner sample. Indeed the birth of a new burner creates automatically its assembly frame/tooling and the first manufactured piece, after RnD’s approval, is used as sample for the next production. Only in this way there is assurance that production will be consistent with the RnD directions. Flam Gas’s sub company is the sole firm responsible for the task of pressing and boring holes in the element, and was founded for this precise purpose. |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

Warehouse |

|

| |

|

|

| |

Once machining is complete, products are stored in a designated area inside the facility: the warehouse. If manufacturing entails galvanic treatments, finished products are placed in special containers and sent to the electroforming and electroplating centre. Once returned, they undergo checks and are numbered. Next, they are placed in boxes stacked on a pallet and stored until dispatch. This last phase is also applicable to products that do not require galvanic treatments, and items in stainless steel. Raw materials such as pipes, sheet metal, bands etc. are subjected to acceptance tests on delivery and kept in the store until they are actually used. Once checked, the components – whether produced by Flam Gas or an independent supplier – are stored in a special automatic warehouse located near the assembly department so that they are easy to get hold of without pointless time wasting. |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

Quality-Adjustments |

|

| |

|

|

| |

No manufacturing concern would be complete without a department like this one. Flam Gas is no exception and has always maintained that the department is the key to the company’s constant production flow. Engineers make skilful use of their experience to prototype burners. The department is also concerned with altering commercially sourced equipment, adapting it to meet the strictest production standards. The team of engineers is headed by the production manager. |

|

| |

|

|

| |

|

|

| |

|

|

| |

Acting on input from the various department heads, the team takes prompt action to solve any production-related problems encountered, whether they regard machine and equipment faults, or technical difficulties with the product’s manufacture. At the risk of sounding presumptuous, we can safely say that this department spawns masterpieces of engineering and automation, in no way inferior to those of top design firms. The material produced by engineers working in this department is forwarded to the production manager who ensures that a written record is made of everything and suitably filed. This procedure is performed with the aid of a modern CAD-CAM station where each part designed is converted into a drawing, meaning the customer gets a realtime update on burner developments and dimensions. Forwarding the informational material to the manufacturer allows him to ascertain, with delay, whether the design is feasible and liable to be effective. Quick and accurate information thus enables research to be steered towards the manufacturer’s actual expectations. This method proves both simple and effective, and also saves the customer pointless time wasting and the higher product costs that would otherwise ensue. |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

Information, feedback, data aquired during the operation of all departments are under continuous assesment, leading to revisions of training procedures and providing quality feedback to development. |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|